Frequently Asked Questions

No, our technology allows us to paint sizeable and heavy parts, but we are capable of painting smaller products or large number series of smaller products while optimally using our capacity. We currently paint products from 0.5 kg up to 2.3 tons.

Every material has a specific process to achieve an optimal surface before painting. We prepare the aluminum either mechanically or chemically, steel mechanically or chemically, where the chemical process has a different formula for each material and happens in a different chamber. For specific projects with requests for extreme anticorrosive resistance, we implement mechanical and chemical pretreatment. We only use mechanical pretreatment for stainless steel parts.

Our paint shop is certified according to ISO 9001 and all technological processes are set according to the Qualicoat standard.

We use a whole spectrum of pains and suppliers based on our customers' desires. We ensure special shades in RAL. Most applications are currently from paint suppliers: Akzonobel, IGP, Aksalta, and Tiger.

The multi-layer coating ensures higher anticorrosive resistance (iron - 480 hours in a neutral salt chamber, aluminum - 1500 hours in an acidic salt chamber).

Yes, we offer other processes for the needs of our customers - for example bonding, which takes place in a separate room with a controlled environment. We ensure surface sanding, minor assembly, putting up insulation. We also have a mechanical shop, apart from external jobs it enables us to make all necessary products for coating at home, fast and cost-efficient.

Most of our customers are from the Czech Republic, but we are proud of our painted products being seen all over the world. Trains with air conditioners painted by our employees ride around not only Europe but also Japan, the USA, South Africa. The seats in the arena of the NHL hockey team Seattle Krakens were painted in our paint shop.

Currently, we still have 40% free capacity and our technologies enable capacity increase by adding employees to other shifts. We can guarantee capacity concerning our customers' sought-after volume.

Our paint shop’s application

LOOK THROUGH OUR RESULTSEstablishment

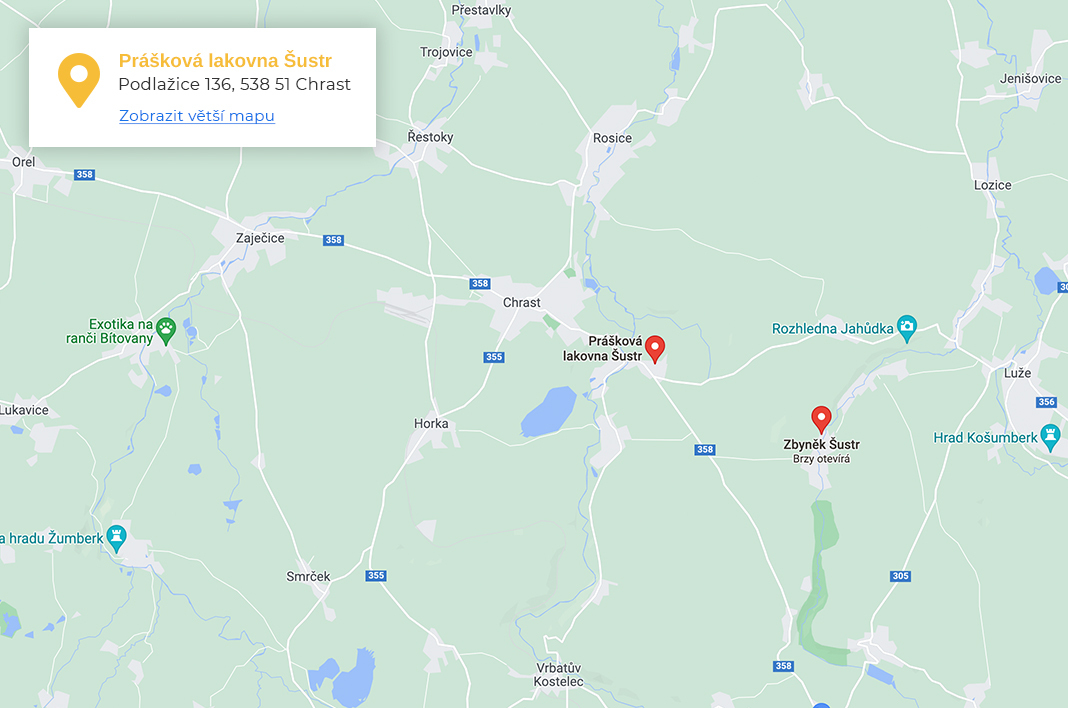

- Podlažice 136, 538 51, Okres Chrudim

Billing address:

- Zbyněk Šustr s.r.o. | Podlažice 136, 538 51 Chrast

- IN 28784278 | TIN CZ28784278

Demands

- info@sustrgroup.com | +420 777 308 776 (and international trade)